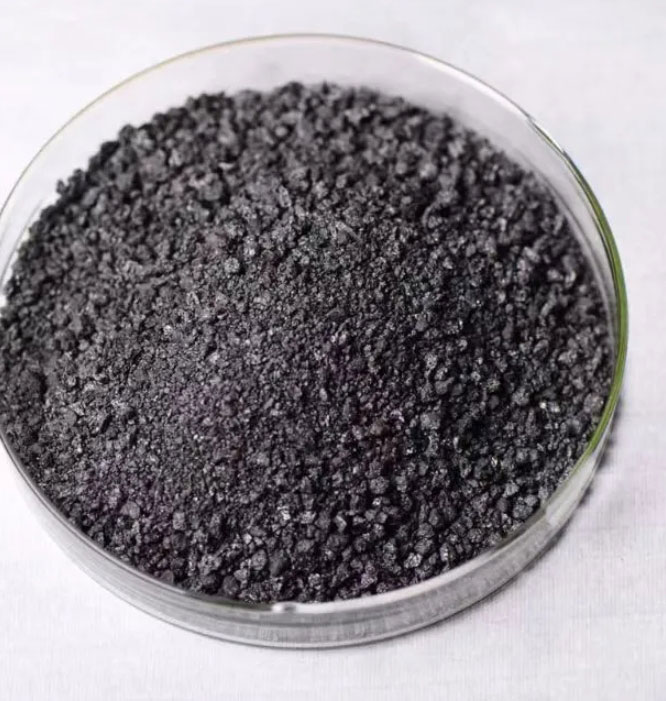

Graphite Petroleum COke is a crucial raw material for various industrial processes. It is used in the production of steel, in the aluminum smelting process, as a carbon additif, and to manufacture graphite electrodes. In these applications, GPC provides quality and consistency that contribute to improved product performance, efficiency, and safety.

Depending on its type and production method, petroleum coke has different densities. This characteristic affects the way it is stored, transported and applied. GPC that is high in density can be difficult for some people to handle. Low-density petroleum coal, on the other hand, is easier to transport and work with. Low-density petrol coke is also more resistant to temperature and pressure variations.

The use petroleum coke in industry can have an impact on the air quality. The combustion can produce fine particulates as well as greenhouse gases like CO2. This can lead both to air pollution as well as climate change. For this reason, government agencies are constantly monitoring emissions from GPC plants.

GPC improves the quality and durability of steel products by acting as a carbon-source in the steelmaking. Specifically, GPC is added to electric arc furnaces (EAF) or ladle-furnace (LF) refinement processes. It increases carbon content, which reduces formation of slags and allows for stronger steel.

In addition, low-sulfur petroleum coke is used to produce high-purity electrodes of graphite for aluminum electrolytic cell in aluminum smelting. Its chemical stability and low resistivity are important in reducing power loss, and improving the service life of the anode. The quality of petroleum coke for electrodes must meet very strict specifications, including a low impurity content and uniform particle size distribution.

Graphite Petroleum Coke is also an integral component in the manufacturing of high-performance brake pads and friction materials. Its lubricating abilities reduce heat generation during braking, clutch engagement and improve performance. GPC is also known for its high thermal conduction and uniform particle size distribution. This makes it a great choice for energy efficient battery production.

Sustainability is a growing priority for many industries, including the graphite petroleum coke industry. This is due in part to the growing awareness about the need to protect resources and minimize environmental impacts. In response to this, there is a trend toward sustainable sourcing and alternative production methods. This involves implementing responsible mining practices, promoting transparency in the supply chain, supporting local communities where raw materials are extracted, and minimizing ecological disruption.

Several companies are also working to improve GPC recycling. This allows them to reduce their energy consumption and save natural resources while avoiding waste management costs. In some cases these efforts include reclaiming GPC from other uses and returning it to production. This is known as the circular economy and it helps to maximize the value of this resource while lowering the environmental footprint of the steelmaking or aluminum production process.

Write a Message