The article Steelmaking using High-quality Petroleum Coke is about a way to make steel more efficiently by using oil instead of coal. This recipe can be made much faster than the default or heavy oil alternative, and requires only a fraction as much coal for smelting. It is less resource-efficient than the default recipe or the Electrode scrap recipe (which uses Graphite in place of Coal).

The solid petroleum coke produced by refineries is an important by-product. It contains approximately 90% fixed carbon, and a very small amount of sulfur. It also has good chemical stability, a low amount of ash and a high calorific content. It is generally used as a substitute for coal in heaters and boilers because it burns more cleanly and has a higher thermal efficiency. It's also used as a fuel for electric energy generation and as a raw material in kilns. Due to its low impurity content and stable structure, it is used for the production of graphite electrodes in the aluminum industry.

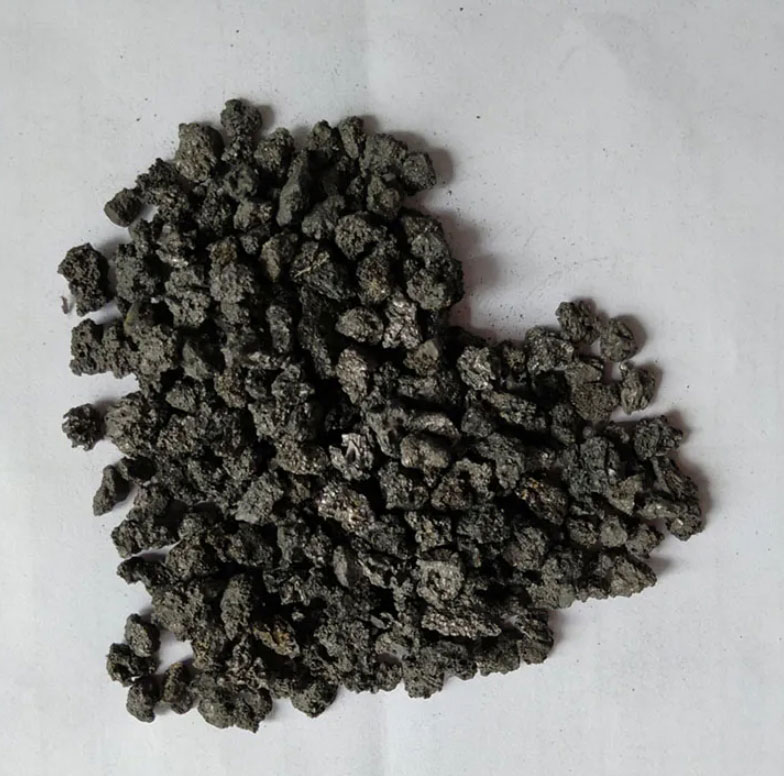

Petcoke is classified according to its origin and uses. There are five types: fuel-grade, calcined Petroleum Coke (CPC), sponge coke, needle coke, and spherical petcoke. Different types of petcoke are differentiated by their different formation processes, and also their physical characteristics. This in turn influences their uses. The pore size and porosity of petroleum coke determines its ability to absorb gases and liquids, as well as its reaction activity. Fuel-grade coal is dense and dark in color. CPC has a lighter color and is less dense. Needle coke has a needle-like shape and is usually darker and more porous than CPC. Sponge coal is more flexible. It has a texture similar to sponge. Spherical Coke is also known as Projectile Coke. It is formed of hard, small particles that form from crudes with low quality or those that have been delayed in coking. It is more expensive than needle coke, but it has a higher capacity to absorb liquids and gases.

Up until recently, petroleum coke wasn't commonly used to replace coal in iron-making processes that utilize a melter. In the present invention, petroleum coke is advantageously used to replace coal as a reductant source in iron-making processes using a melter gasifier. This is because it contains a high percentage of carbon monoxide reduction gas.

The high CO levels in the reducing gas reduce sintering and clustering. This results in improved productivity and quality of the finished steel product. This method is more eco-friendly than the direct reduction using natural gas.

Write a Message