El coque de petroleo (petcoke) desempe

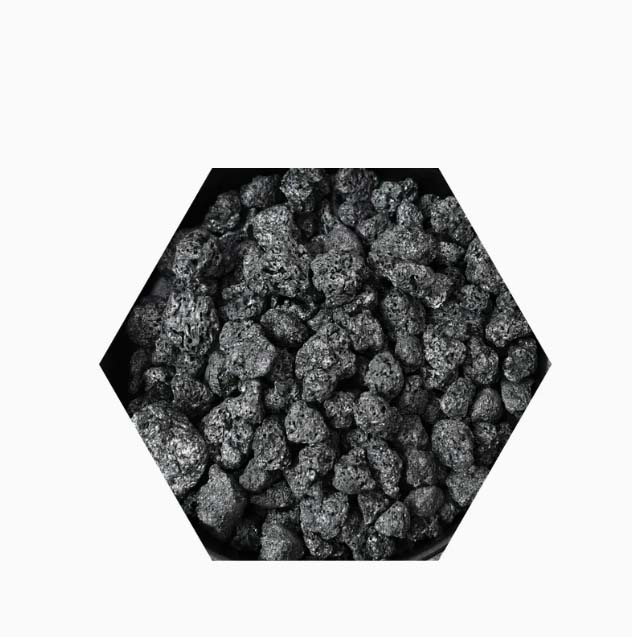

Petroleum coke is a solid, black organic material that is a byproduct of crude oil refining. It is high in carbon with low sulphur, and has an ash content. The coke can either be created by a destructive process of distillation at petroleum refineries, a geological process or as a result from a destructive distilation. Coke is used in a number of industries, especially for power generation and in the production of aluminum and other metals.

The steel production process requires the use a carbon-bearing substance to remove the oxygen from iron oxide (hematite), and then convert it into molten (pig) iron. The most common carbon source is petroleum coke, but other sources such as natural gas and biocoke have been considered as alternatives.

The metallurgical processes in the steel industry produce a large amount of emissions. These include the coke-making and sintering processes as well as the blast furnace (BF) melting and smelting of iron ore. Nearly 90 percent of emissions in the industry are a direct result of energy consumption and associated greenhouse gases. Hence it is important to find alternatives that are both environmentally friendly and cost-effective.

Most petroleum coke today is used for electricity generation and as fuel in cement kilns. This is because it's an affordable, relatively clean energy. As a fossil fuel, petroleum coke emits much less greenhouse gases than coal. The high sulfur content and ash can create problems for coal-fired power stations and concrete manufacturing. A high sulfur content in finished concrete can increase its expansion, reducing its lifespan. Sulfur can also prevent the combustion of volatile substances in a furnace.

In the steelmaking sector, petroleum coke is commonly used in the production of aluminum, as a fuel in the calcination of bauxite and as an addition to the coal in the electric arc furnace (EAF) for steelmaking. The main disadvantage of using coke in the steelmaking process is its ash content. To prevent unwanted reactions, the ash content in conventional and nonconventional carbon should be as low as possible.

Compared to calcined petroleum coke, torrefied wood and biochar exhibit lower ash contents. These renewable carbon alternatives can therefore replace the traditional carbon sources used in EAFs. These renewable carbon sources have a reactivity that is comparable to calcined petroleum coal, but with a higher sulphur content and fixed carbon. However, a more thorough study is required to assess the potential of these renewable carbon-bearing materials for substitution in the metallurgical processes of EAFs. The usage of these materials should not only be cost-effective, but also provide a sustainable solution in the light of post-Kyoto requirements. It is suggested to investigate the reactivity with these alternative sources in relation to their particular characteristics such as elemental content, sulfur content, moisture content and ash content.

Write a Message