Many factors need to be considered when EDMing exotic materials. Unfortunately, choosing the correct electrode material is often overlooked. As a result, they end up with poor results and higher operating costs. In some cases, the determining factor in selecting the right electrode material may be price, but it is imperative to consider all of the factors involved.

Electrical resistanceivity is amongst the most crucial factors. Electrical resistivity is one of the most important factors. It determines how much energy passes through an electrode before it can be used to strike the workpiece. Also, it determines speed and finish quality. Electrical resistivities of graphite and copper electrodes are very different. Graphite has excellent properties in terms of heat resistance, chemical stability and conductivity.

Copper is more conductive. The high conductivity makes copper ideal for applications in harsh environments or where heat and chemical exposure is possible. But it's not as flexible as graphite.

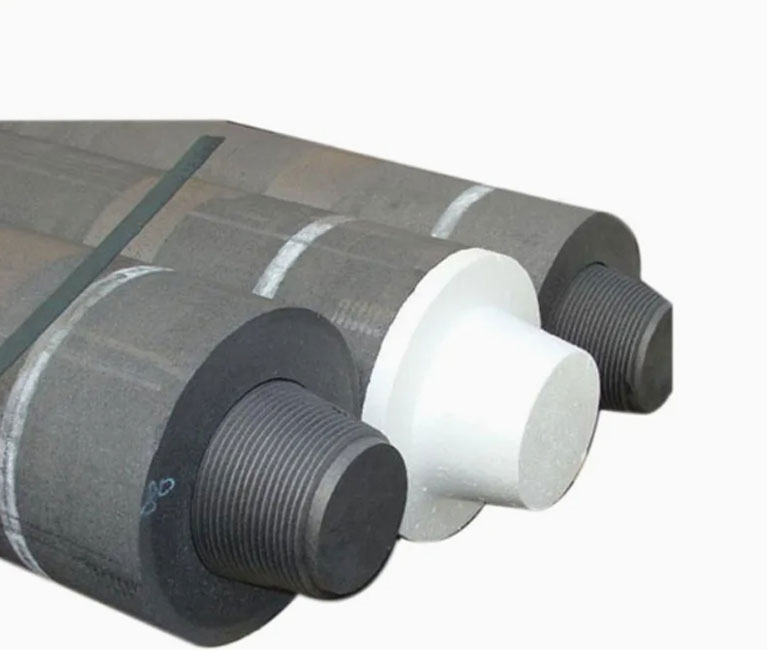

In response, manufacturers began to develop hybrid electrodes which combined the best features of both. The copper-impregnated version of graphite provides a good example. Copper lowers graphite’s electrical resistance, increasing energy flow to the workpiece while removing more metal. While providing excellent wear resistance for electrodes, the graphite also provides increased machining flexibility.

En plus, using hybrid electrodes can help save man hours compared to copper-based traditional ones. Electrodes are needed for a copper piece measuring 300 x150x70mm. But if you use graphite, that same size is only around 5kg. Moreover, by machining the whole electrode in one step, it eliminates rework, polishing costs and time.

Copper or graphite? The decision is completely based on the application. Copper has a better suitability for high speed, high quality machining, while graphite can process workpieces in large quantities and with low resolution. In certain cases it is cheaper than copper.

For both graphite and copper, it is important to consider the pulse gap/pulse width ratio when machining with electrical discharge. Larger pulse gaps can increase surface granularity as well as processing stability. This can, however, reduce the current and lead to an increase in electrode loss. In contrast, using a small pulse gap leads to higher speeds and less electrode loss. However, the surface roughness is increased. When using a graphite electrode, it's recommended to set the pulse gap at a middle value. The surface will be of a very high quality and the processing speed is high. A material's average particle diameter also has a direct impact on the discharge condition and the quality of its surface. The greater the uniformity and stability of discharge, the smaller average particle size.

Write a Message